How Are Large LED Advertising Screens Powered? Revealing the Secret of Sequential LED Module Lighting

Have you ever noticed that outdoor LED advertising screens don’t light up all at once? Instead, they illuminate module by module. Why does this happen?

This phenomenon is actually related to the power supply and control system design of LED display screens.

🔹 Principle of Block-by-Block Power Supply

Large LED screens are usually composed of multiple LED display modules.

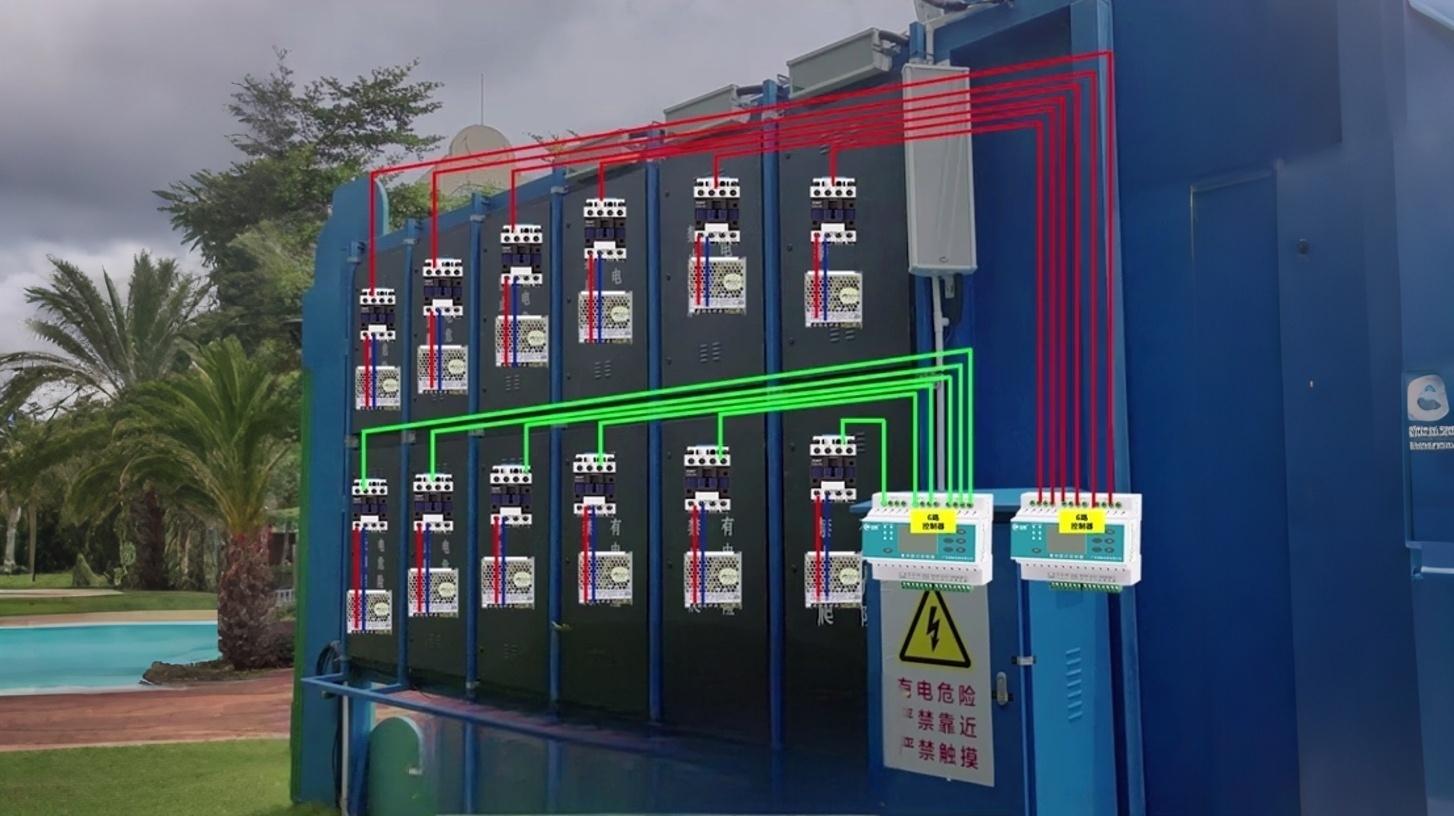

Take a screen made of 12 LED modules as an example:

- Each module is equipped with an independent contactor and switching power supply.

- The distribution box contains two 6-channel controllers, responsible for overall coordination.

Control process:

- The controllers sequentially trigger the contactors of each LED module.

- Once a contactor is activated, the corresponding switching power supply is turned on.

- The switching power supply then powers the respective LED module.

🔹 Why Sequential Lighting Is Necessary

- Reduce instantaneous current surges: If all modules power on simultaneously, the sudden current spike can overload the power supply or contactors.

- Protect hardware: Sequential startup reduces voltage fluctuations that can damage LED modules, extending screen lifespan.

- Smooth startup experience: Gradually lighting up modules ensures a safer and more stable power-on process.

💡 This is why outdoor advertising screens, stage LED walls, and stadium LED screens always light up in a rhythmic, sequential manner.

🔹 Interactive Question for Readers

Have you ever noticed this sequential module lighting on streets or at concerts? Besides protecting hardware, what other advantages do you think this design provides?