Why Mixing Different Batch Modules Risks Performance & How to Mitigate

For professionals in the LED display industry—whether project managers, system integrators, or technical leads—module selection and installation directly impact project success. A common but critical mistake? Mixing LED screen modules from different batches. While it may seem like a quick fix for inventory gaps or project deadlines, this practice often leads to costly issues down the line. Let’s break down the risks, share actionable best practices, and help you keep your LED projects on track.

The Hidden Risks of Batch-Mixed LED Modules

Even with modules of the same model, production batch variations create unseen inconsistencies that surface once installed:

• Display quality degradation: LED beads from different batches often have subtle differences in brightness and color temperature. Individually unnoticeable, these discrepancies become glaringly obvious in a spliced screen—think uneven brightness, color shifts (reddish/bluish patches), or inconsistent contrast. For client-facing projects like retail digital signage, corporate lobbies, or event stages, this directly harms brand perception.

• Component failure & shortened lifespan: Core components (driver ICs, resistors, capacitors) vary slightly in voltage/current parameters across batches. Mismatched parts cause flickering, image retention, or even overcurrent damage. This not only increases maintenance downtime but also cuts the screen’s service life—turning a “cost-saving” mix into a long-term financial drain.

• Structural & aesthetic flaws: Tiny variations in frame thickness or circuit board dimensions (common across batches) accumulate in large-scale installations. The result? Uneven seams, black gaps, or bulging panels—major red flags for high-end projects like conference room video walls or luxury retail displays.

Best Practices for Safe Module Usage (Even When Mixing Is Unavoidable)

We get it: project constraints sometimes force batch mixing. When that’s the case, follow these industry-proven guidelines to minimize risk:

1. Batch-concentrated installation: Group modules from the same batch together, and reserve different batches for edge positions (not core display areas). This limits visual disruption and keeps key content consistent.

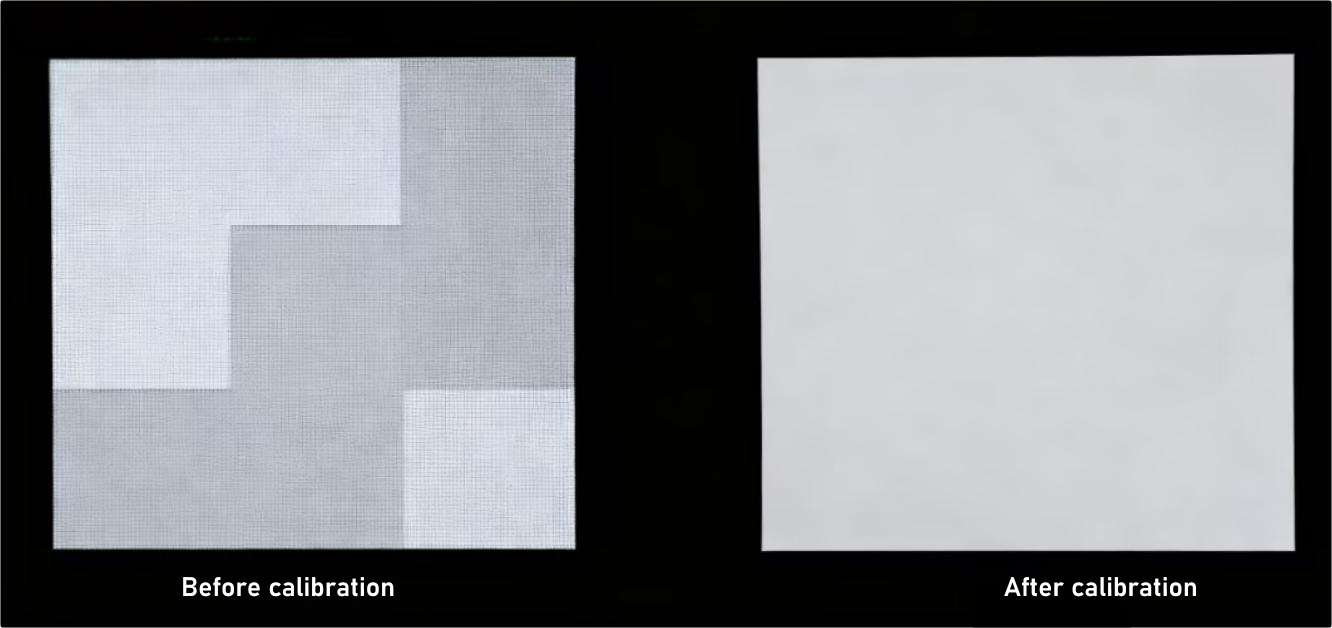

2. Pre-installation calibration: Test every module individually before mounting. Use professional tools to calibrate brightness, color, and gamma values—ensuring uniformity across the entire screen.

3. Strict ratio control: Limit non-matching batches to ≤5% of the total module count. Exceeding this threshold makes calibration ineffective, and issues will resurface within months.

Pro Tips to Avoid Batch-Related Headaches

Color inconsistency and batch variations are industry-wide challenges—but they’re avoidable with proactive planning:

• Source modules from a single brand/model to align production standards and component quality.

• Leverage advanced LED calibration software to unify color profiles, even for modules with minor batch differences.

• Prioritize regular maintenance: Dust removal, temperature control, and periodic recalibration preserve display integrity and extend lifespan.

In the LED display space, attention to detail separates successful projects from costly do-overs. By prioritizing batch consistency and following structured installation protocols, you’ll deliver reliable, high-quality results that impress clients and stand the test of time.

What’s your biggest challenge when managing LED screen projects? Whether it’s inventory shortages, calibration hurdles, or client-specific display demands, let’s discuss in the comments—sharing insights that elevate our industry together.

Avoid costly LED display failures! Learn the hidden risks of mixing different batch LED screen modules—uneven brightness, component damage, and structural flaws. Discover industry-proven best practices for batch-concentrated installation, pre-calibration, and ratio control to ensure consistent performance in LED video walls, commercial signage, and indoor displays. Essential guide for LED project managers, system integrators, and technical professionals aiming to deliver reliable, high-quality LED projects.